metal finishing robotic machine

In the orthopedical sector, innovation and precision are essential Our deep experience and expertise have enabled us to create highly specialized robotic machines that are distinct for different orthopedic applications. Our know-how covers four areas of the orthopedic field: femoral prostheses, stems, tibial bases, and orthopedic screws.

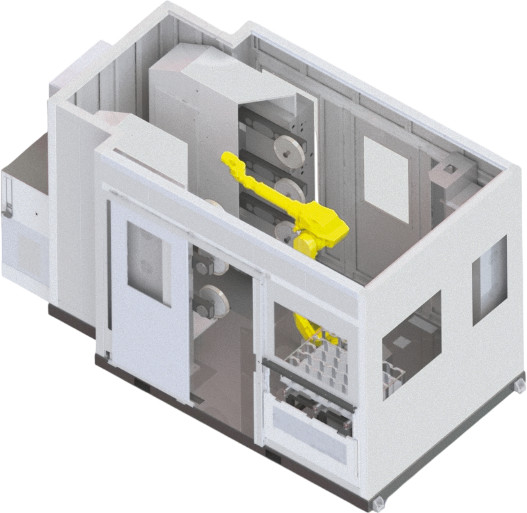

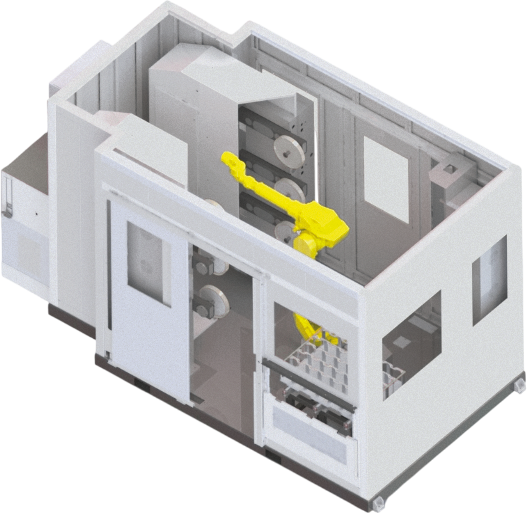

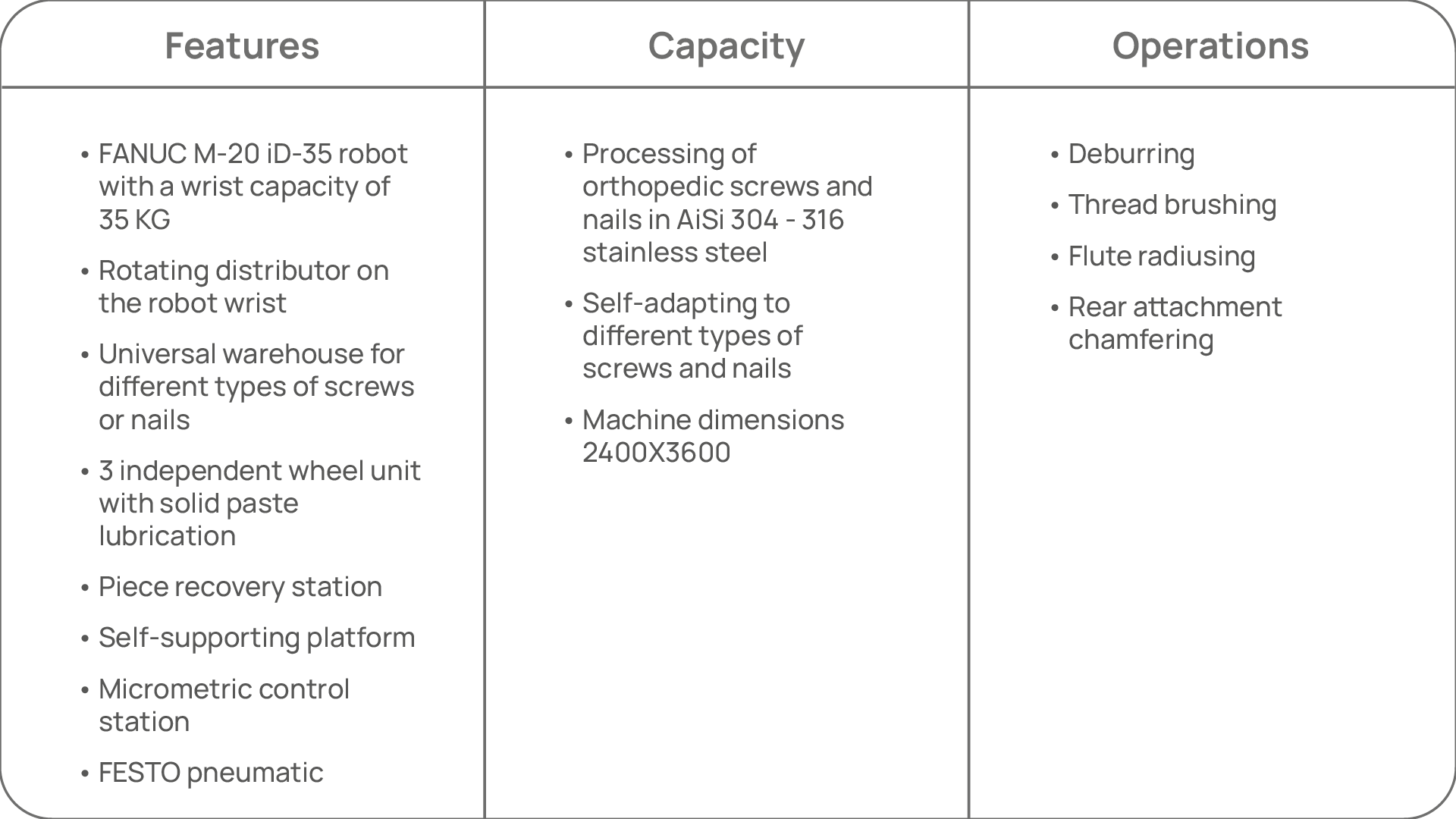

The RS 35 represents an excellent solution for the automated brushing of orthopedic screws and nails. Designed to offer precision and reliability, this robotic system is designed to cover a wide range of sizes and configurations of screws and nails, ensuring accurate and repeatable processing. Thanks to a compact layout, RS 35 reduces the space occupied on the plant, without compromising on efficiency and quality.

The system is completely automated, the robot picks up the piece from the warehouse and subjects it to brushing. The process eliminates residual burrs after the milling, turning and sharpening phases, ensuring a perfectly smooth surface on attachments, threads and tips. A very high-precision control station, equipped with a micrometric profile projector, verifies the quality of each piece, comparing it with the specific CAD model. This ensures that only compliant pieces move on to the next phase. The cycle ends with a thorough washing and blowing to ensure optimal cleaning of the machined pieces. The RS 35 is the ideal solution for those looking for reliability, advanced automation and high performance in the treatment of materials such as AISI 304 and 316 stainless steel.

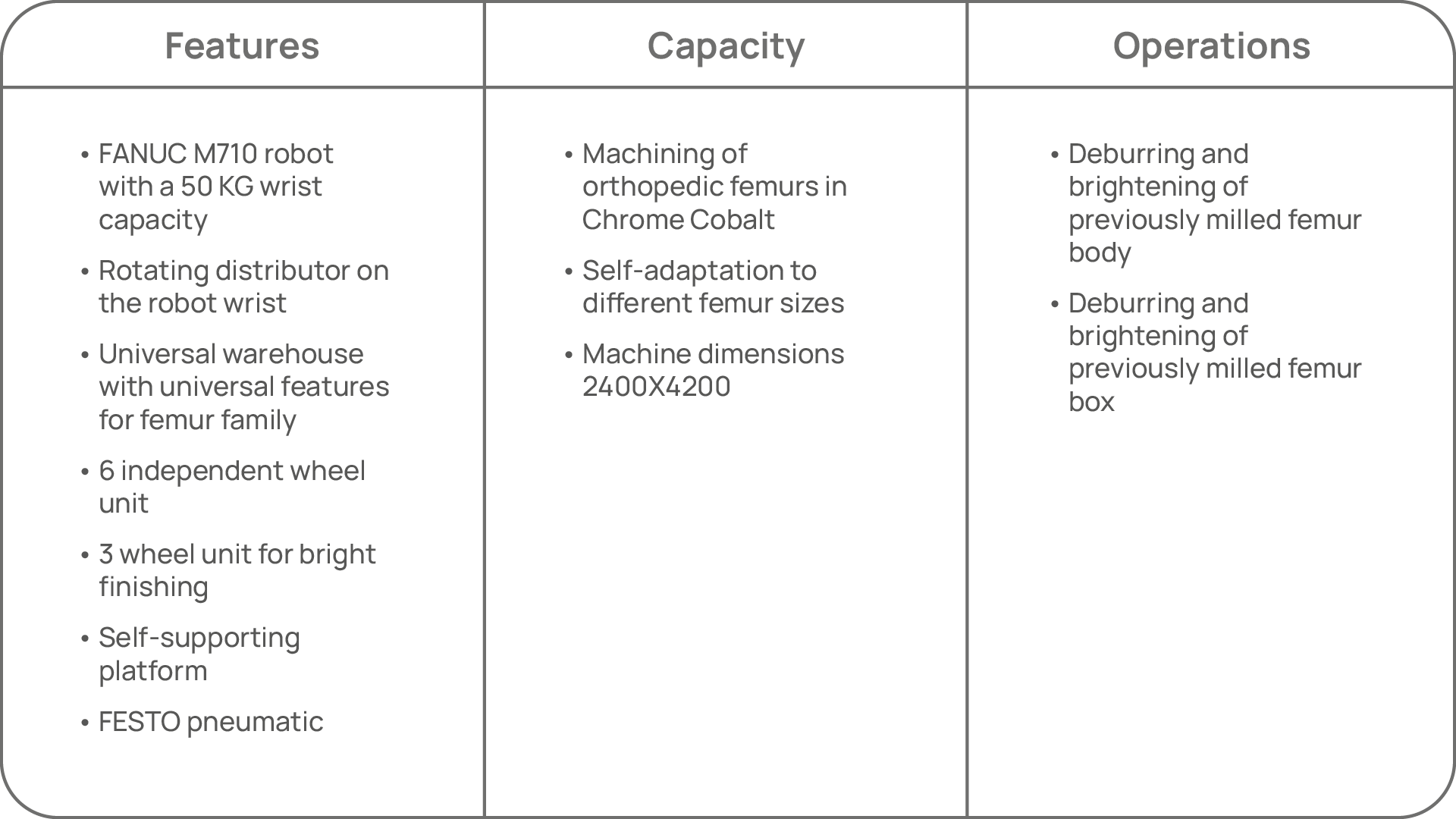

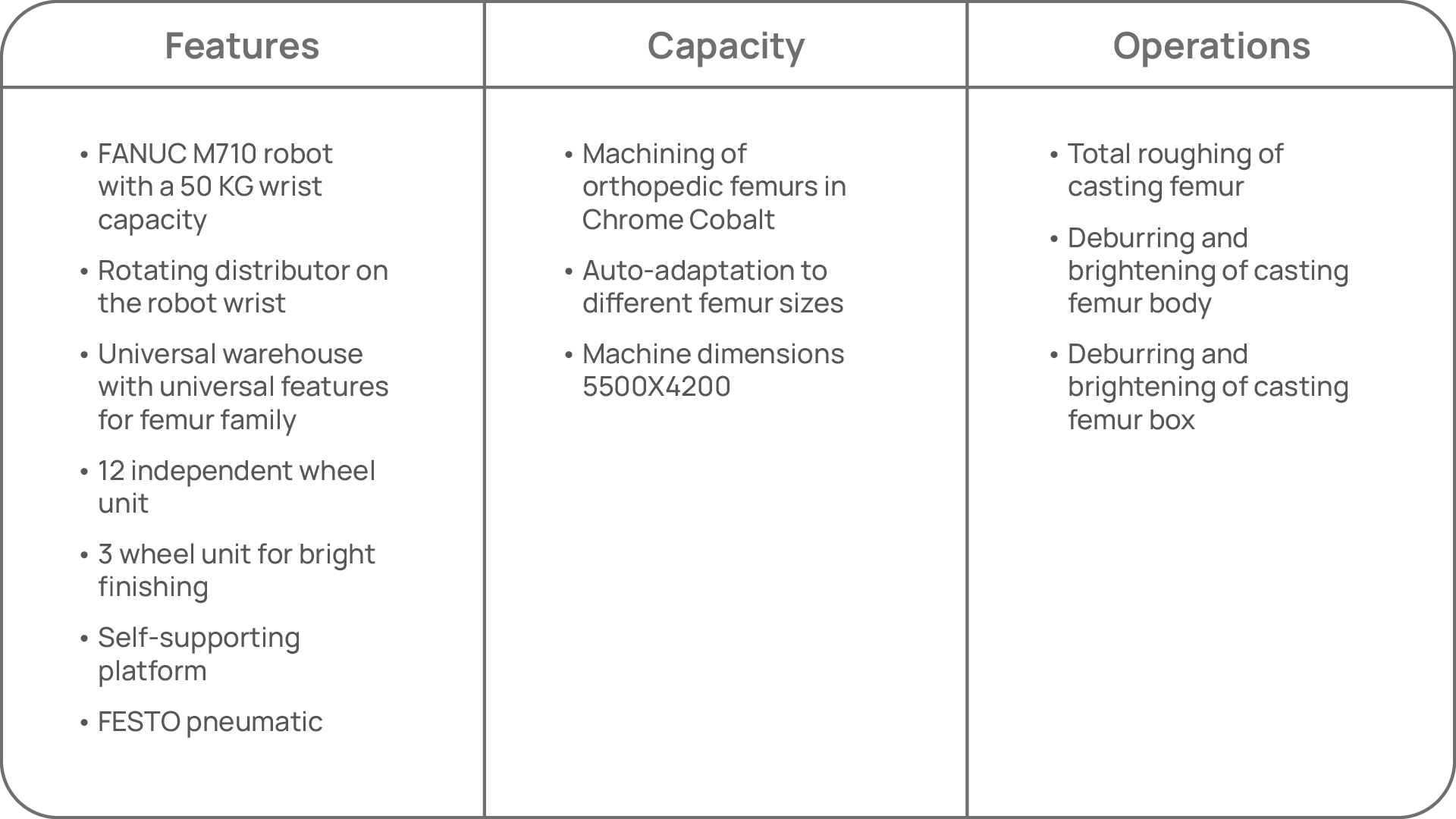

The RSM 800 is RS’s turnkey robotic system designed for grinding previously milled femoral prostheses.

This innovative system has been developed in close collaboration with leading manufacturers in the orthopedic sector, to ensure the perfect combination of efficiency, quality and process duration. The result is an advanced system, capable of offering impeccable levels of finish, exceeding expectations in terms of precision and productivity.

Equipped with 9 fully independent contact wheels, the RSM 800 is able to distribute the workload across multiple abrasive points, ensuring uniform and accurate grinding of the raw femur. The highcapacity sliding warehouse can hold up to 39 femurs, arranged in fixed positions that ensure stability throughout the process. The contact wheels, 6 of which are axially compensated, perform the belt grinding, while the other 3 fixed wheels take care of the super surface finishing. This split approach allows to reach the highest quality standards required by geometric tolerances. With its ability to machine materials such as Cobalt Chrome, the RSM 800 is the ideal choice for prosthetic manufacturers who are looking for optimal performance and long-term quality.

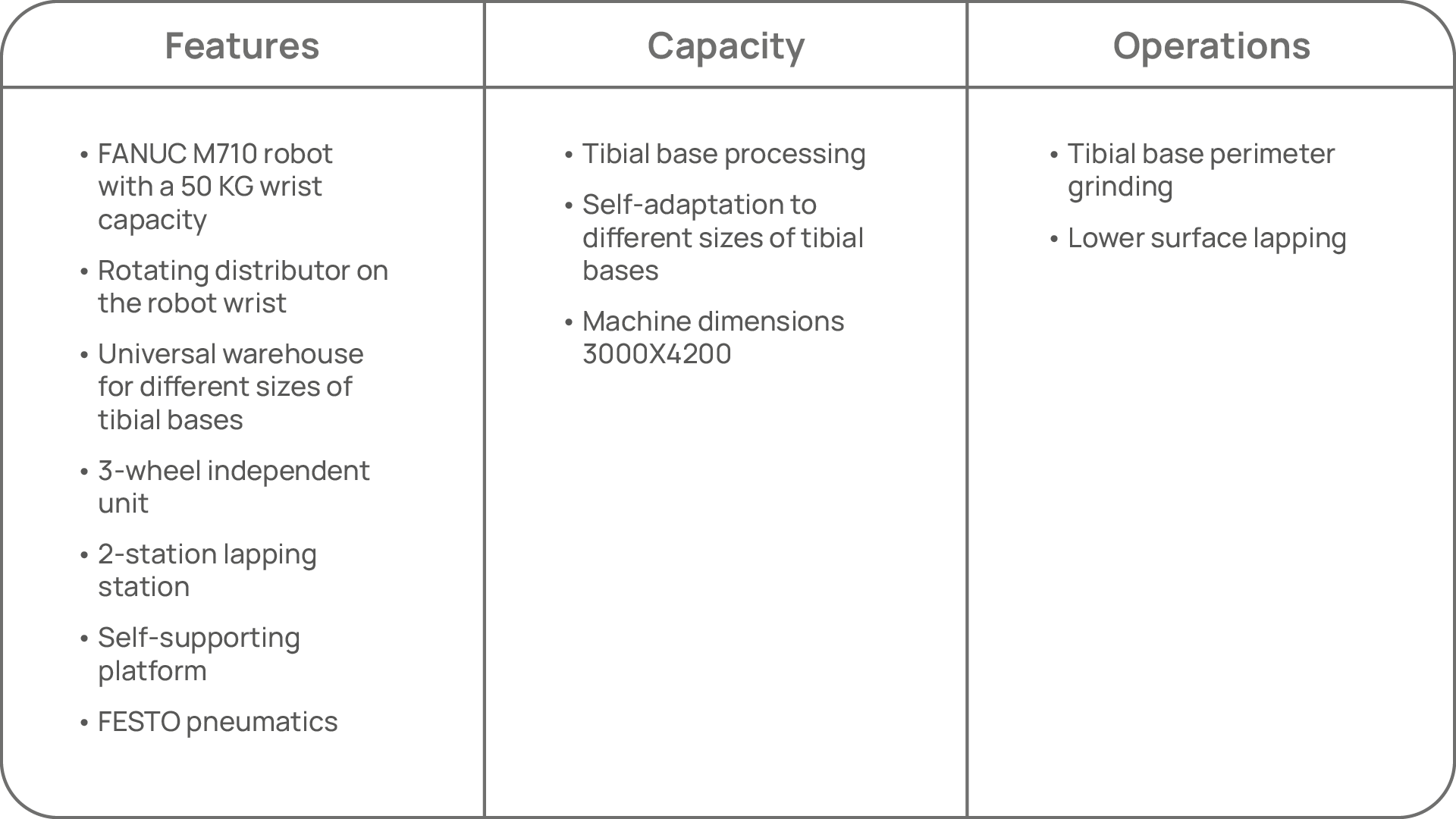

The RSM 850 is the new RS robotic system designed specifically for the grinding of orthopedic tibial bases. This turnkey system offers a dedicated and highly efficient solution for the finishing of crucial orthopedic components such as tibial bases, ensuring precision and repeatability in every production cycle.

The RSM 850 is equipped with 6 fully independent contact wheels, which allow the grinding process to be divided into multiple abrasive points, ensuring uniform and accurate processing of the piece. The system is optimized to process tibial bases obtained from a milling process, significantly reducing cycle times and improving the quality of the final product.

After the tibial base grinding, the lapping process follows, using a dedicated station, the use of two contact surfaces allows for an excellent result in geometric terms and provides high-quality processing in terms of surface finish. The sliding warehouse can hold up to 60 tibial bases, ensuring automated management of the loading and unloading of parts.

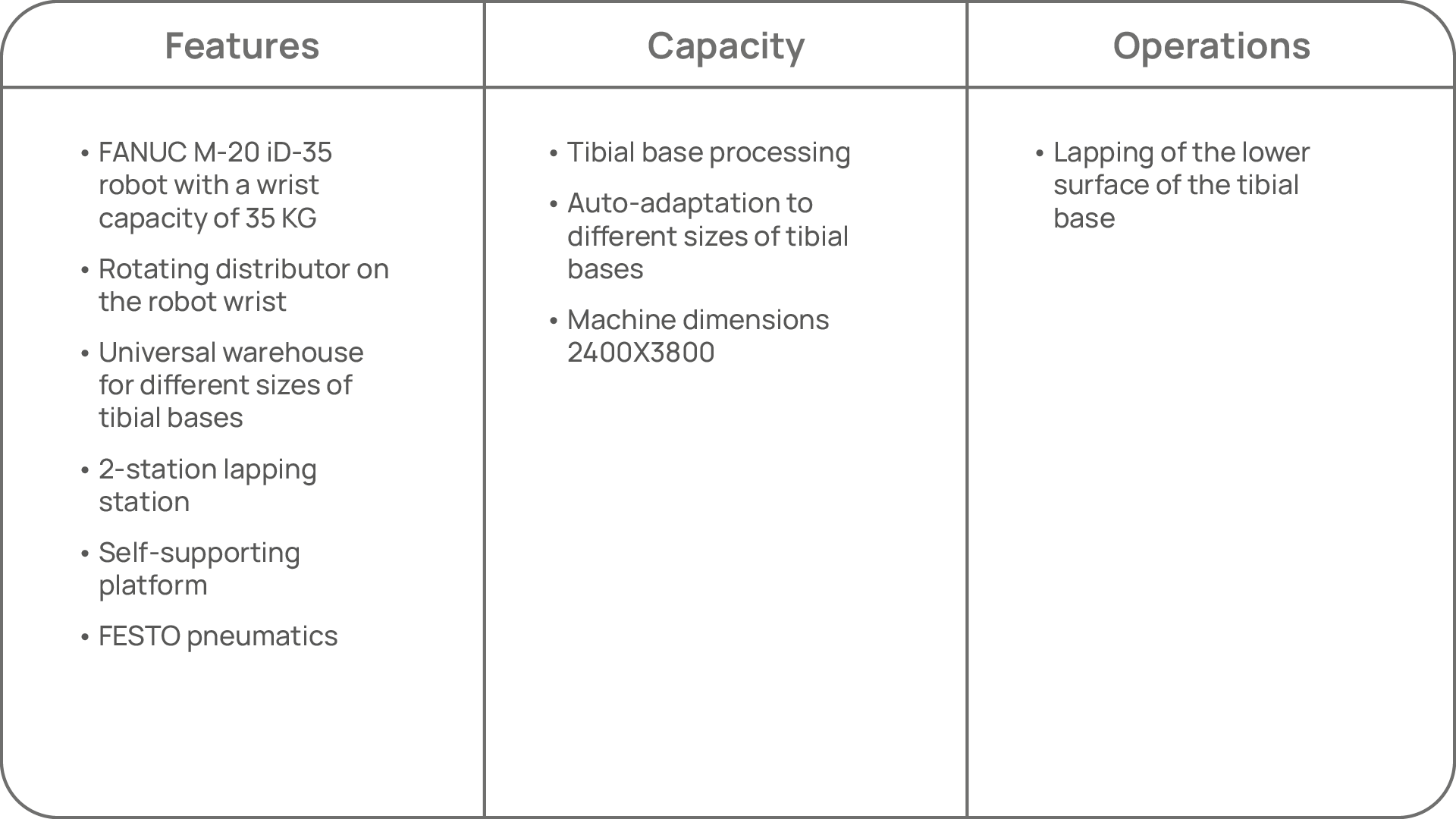

The RSM 880 is the new RS robotic system designed specifically for the lapping of orthopedic tibial bases. This turnkey system offers a dedicated and highly efficient solution for the finishing of crucial orthopedic components such as tibial bases, ensuring precision and repeatability in every production cycle.

The RSM 880 is equipped with 2 completely independent contact planes, which allow the lapping process to be divided into multiple abrasive points, ensuring uniform and accurate machining of the part. The system is optimized for machining tibial bases obtained from a milling process, significantly reducing cycle times and improving the quality of the final product. The sliding magazine can contain up to 60 tibial bases, ensuring automated management of the loading and unloading of the parts.

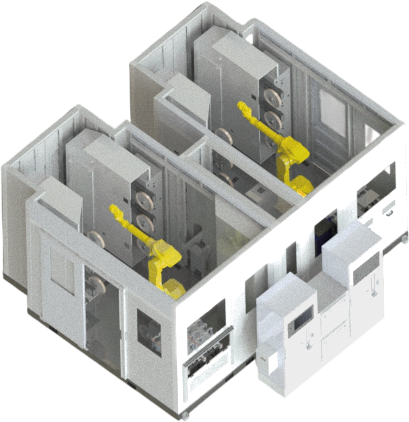

The RS COMBY 800 model is a robotic system dedicated to the grinding of forged femoral prostheses. Designed to offer high performance, this double system stands out for its ability to efficiently manage each phase of the process, from roughing to finishing. Thanks to its advanced technical features, the COMBY 800 represents a turnkey solution for manufacturers who require reliability and precision.

The system is composed of two work machines, connected to each other by a central translator that facilitates the transfer of parts from one phase to the other. The system has 15 independent contact wheels: the first 12, axially compensated, perform the belt grinding, while the last 3 take care of the surface super finishing. This multi-stage process guarantees uniform and high-quality treatment. The sliding warehouse can hold up to 30 femurs, arranged in fixed positions to ensure stability and precision throughout the entire production cycle.

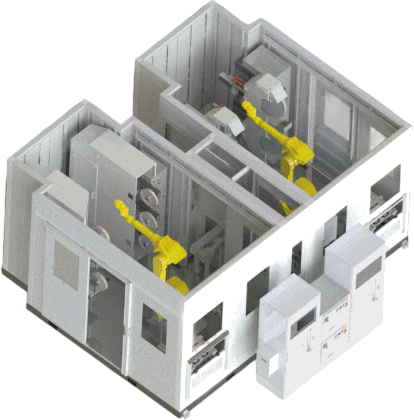

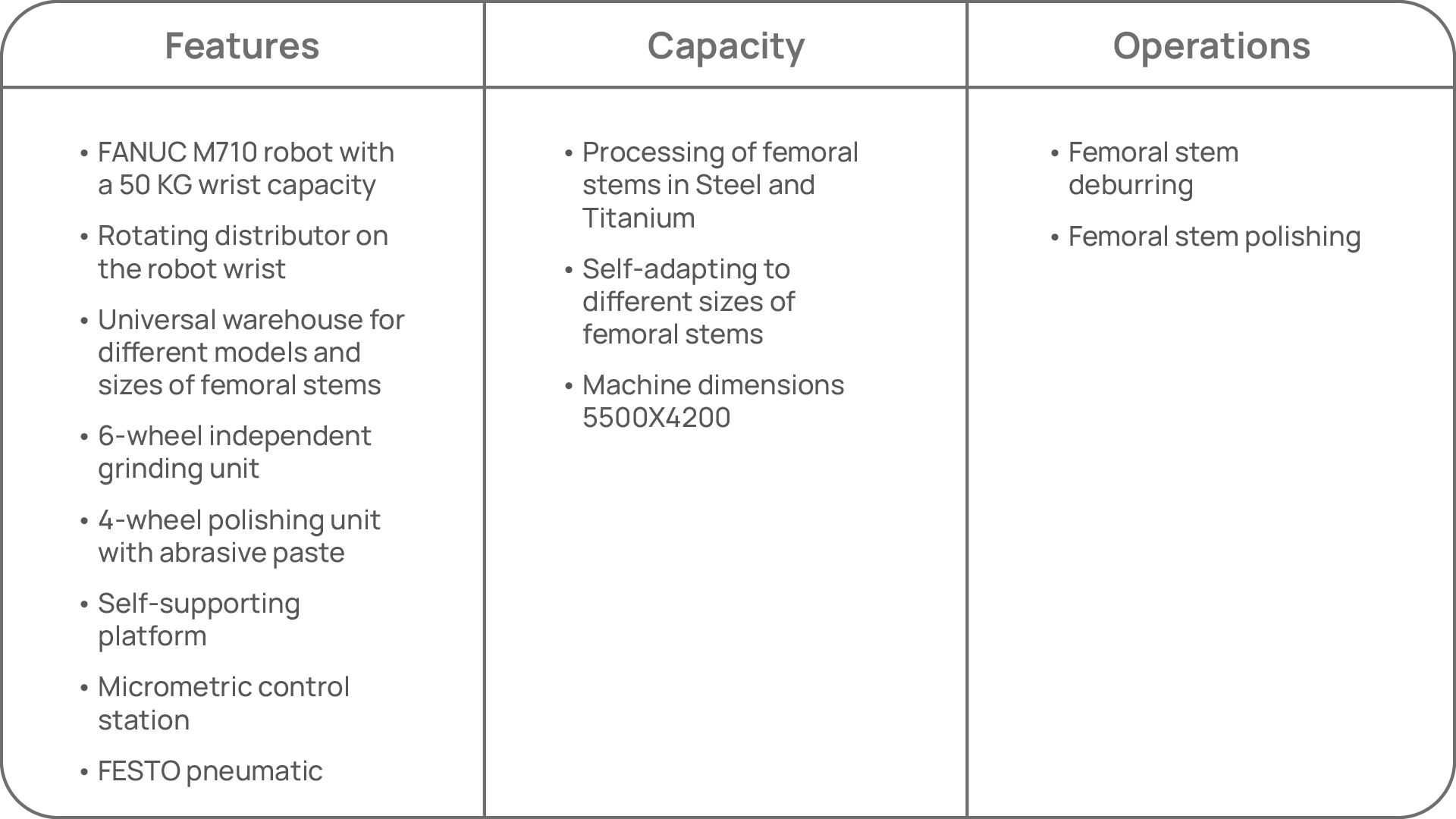

The RS COMBY 900 is the flagship of the RS line for grinding and polishing of forged orthopedic stems. This double system, designed to offer maximum efficiency and precision, is equipped with two operating machiens: the first dedicated to grinding and the second to polishing. Thanks to a modular and flexible layout, the RS COMBY 900 is able to handle stems of different sizes, offering optimal results in every phase of the process.

Machine A, dedicated to grinding, is equipped with 6 independent contact wheels, which allow the raw piece to be machined with extreme precision. Machine B, on the other side, has 4 contact wheels for the final polishing phase, which gives the piece an impeccable finish. The sliding double magazine can contain up to 40 stems, automatically adapting to the different sizes. Quality control is ensured by a micrometric verification station, which uses a profile projector to ensure that each piece falls within the required dimensional tolerances. Materials such as steel and titanium are machined with precision, ensuring the highest quality products, compliant with the most demanding international standards. The COMBY 900 is the perfect choice for manufacturers of orthopedic stems looking for a complete, productive and cutting-edge system.

Our robotic systems are designed to deliver excellent and reliable performance.