metal finishing robotic machine

Our robotic solutions offer a wide range of benefits that revolutionize the production process, enhancing efficiency, quality, and safety. Precision and efficiency are essential, especially in metal processing. Our company stands out in providing advanced solutions for sprue cutting, an essential process for removing excess material from cast parts. Our robotic systems are designed to perform high-precision cuts, ensuring flawless finishes and significantly reducing processing times.

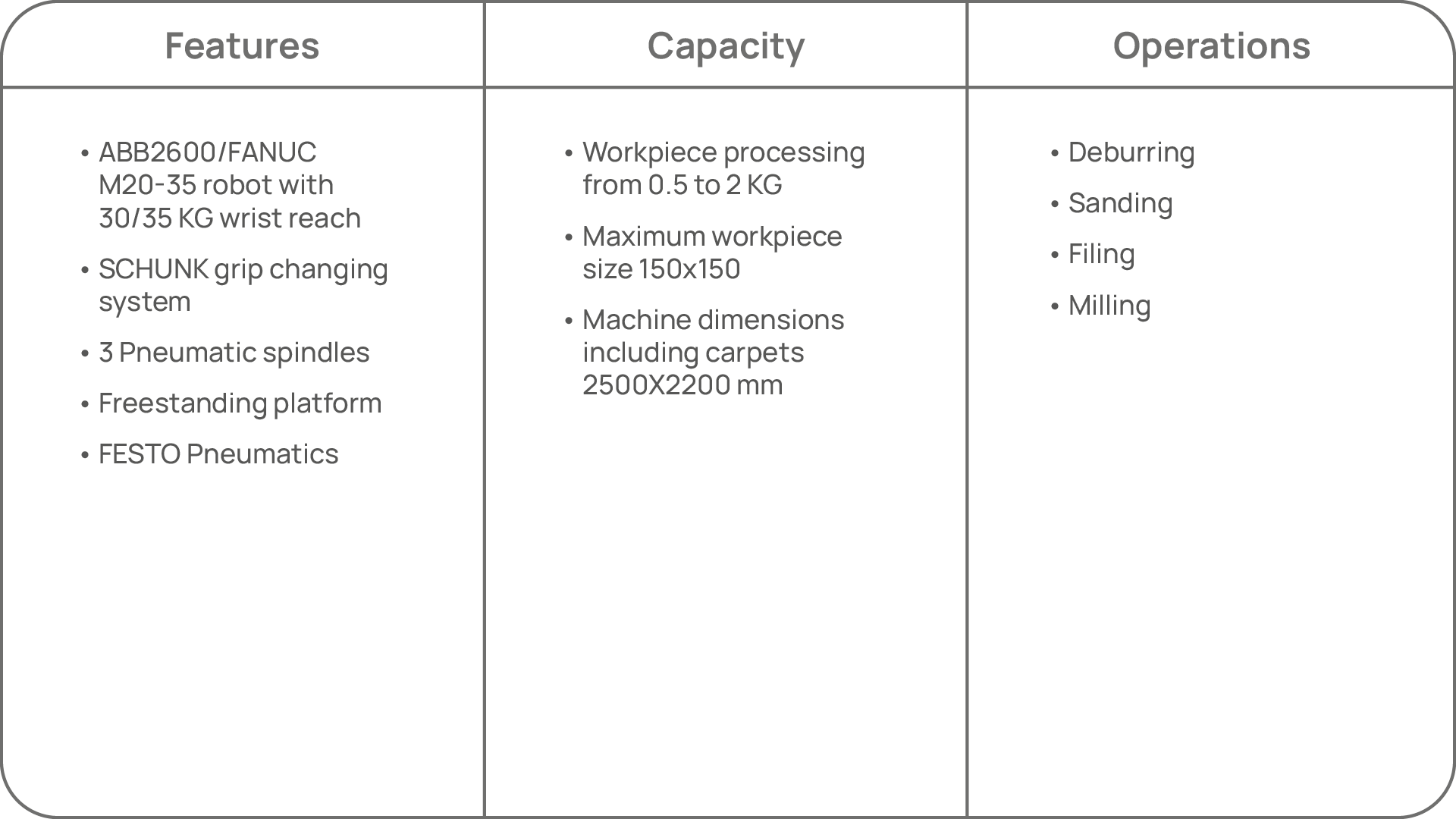

Designed and built with a precise mission, to take up as little space as possible!

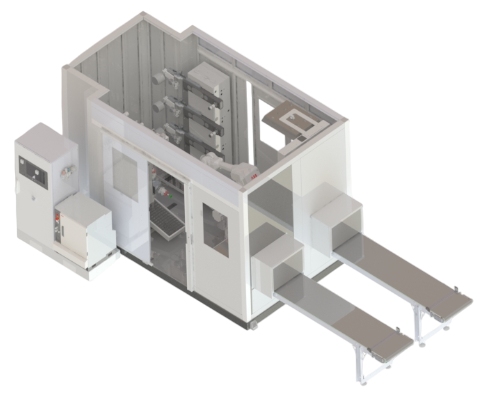

The RS Deburring 30 is the solution idealized by RS dedicated to the companies who do not give up the machining quality of a robotic process but, at the same time, do not have the availability of a sufficient work area.

RS Deburring 30 is a compact system dedicated to the filing, milling and sanding of small components. Thanks to its three-tool central station it is able to carry out three or more different operations. Tools are pneumatic, compensated and they are equipped with an quick change system for quick setup. The system can be configured in different setups, the feeding can take place in line or in total autonomy, the robot picks up the pieces, processes them and releases them in the unloading area.

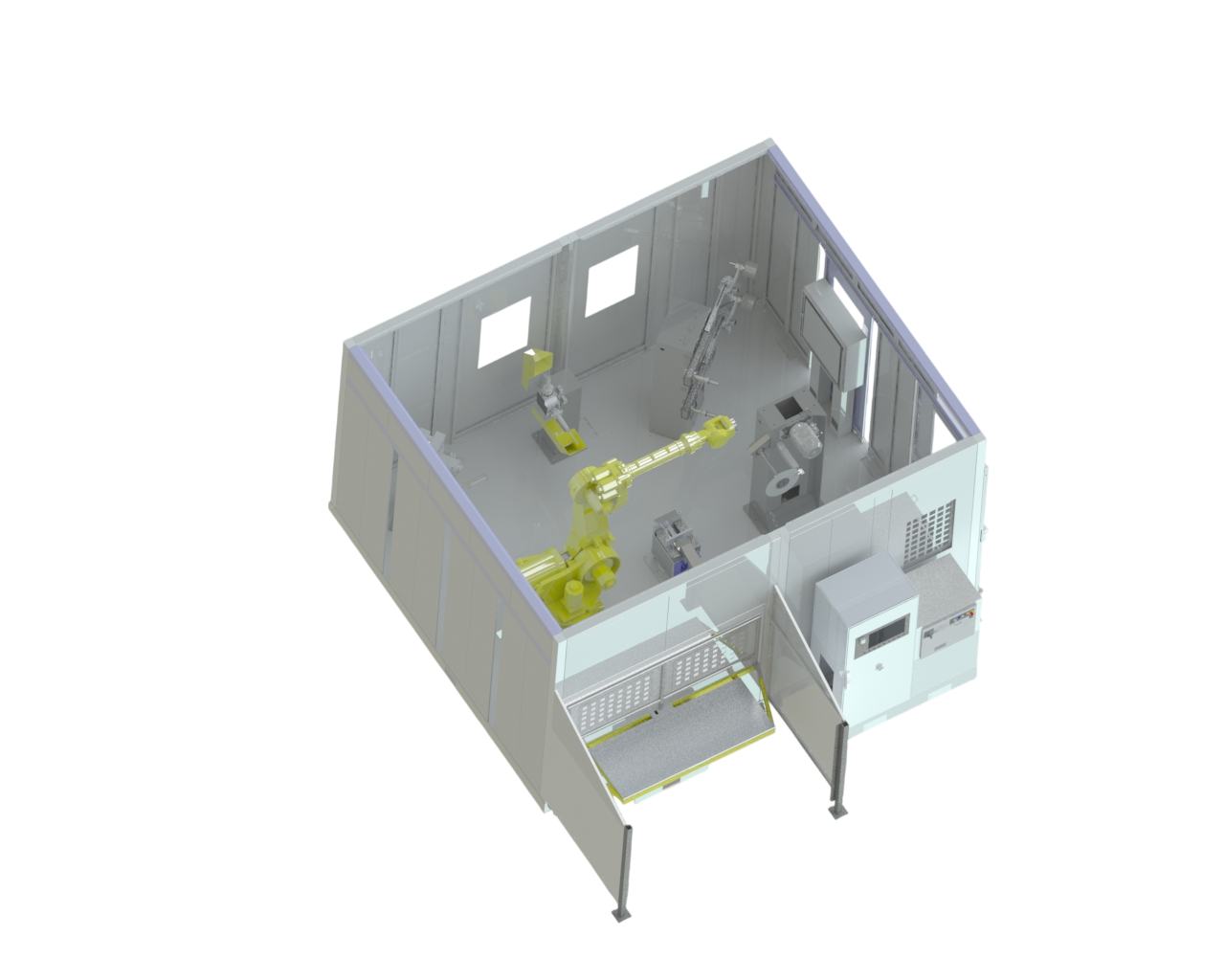

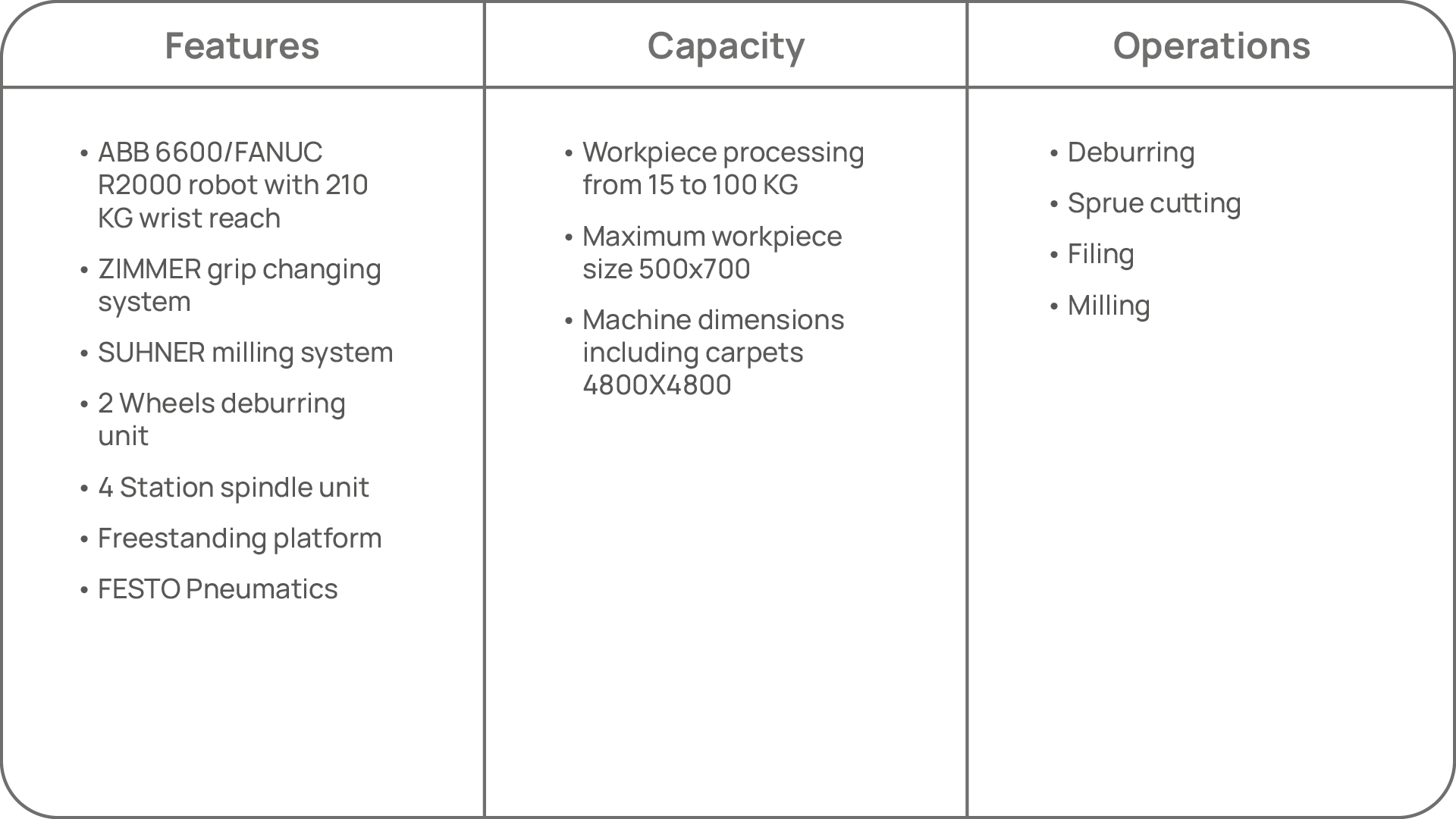

The RS Deburring 45 was born with the mission of providing a unique system, including numerous operations.

RS Deburring 45, thanks to its advanced technical features, allows you to concentrate many operations in a single system.

Ability to process components ranging from 15 to 100 kg, it’s able to perform precise cuts using a cutting station with a disk, grind surfaces, file the most difficult to reach areas and, finally, it is able to mill planes and pockets thanks to the milling station with a conical spindle.

The multiplicity of functions makes it extremely versatile, capable of completing 100% of the operations required on the piece, guarantees a quality and extremely rapid process. Thanks to the features that make it complete, the RS Deburring 45 is among the most complete robotic systems on the market.

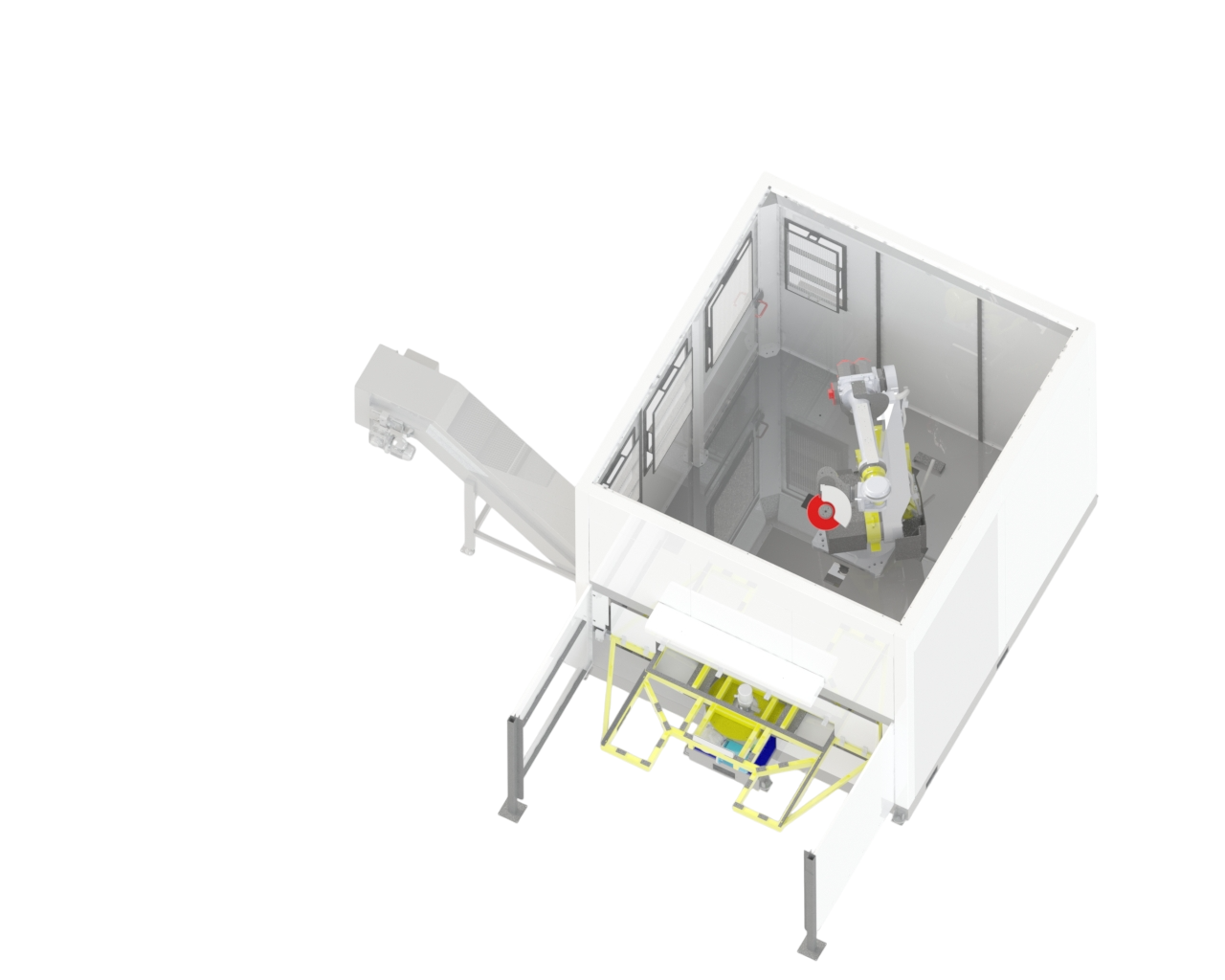

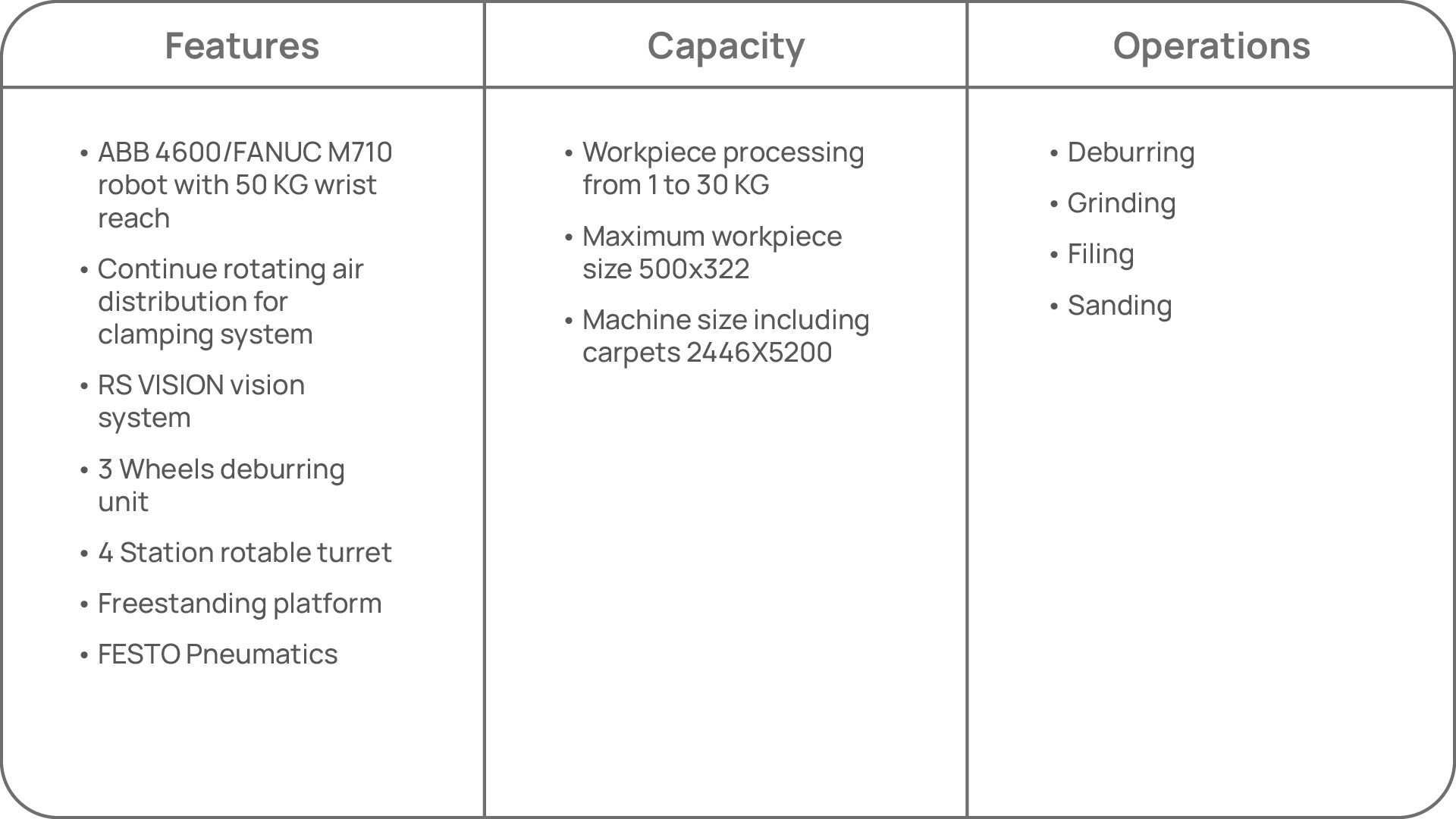

RS Deburring 50, the workhorse for robotic grinding in the automotive sector!

RS Deburring 50 was created with the aim of being a system dedicated to companies that produce different types of cast parts, which must undergo deburring, filing and sanding processes.

The RS Deburring 50, includes the missions in a single solution, is equipped with a belt deburring station on three compensated contact wheels, a flat sanding station and is equipped with a 360° indexed rotating station which allows filing and brushing operations to be performed with four compensated tools. The system is fed versatilely via two conveyors, one for loading and one for unloading, the components rest on the conveyors and are recognized via a precise robot-guided vision system.

The definitive solution for cutting medium castings!

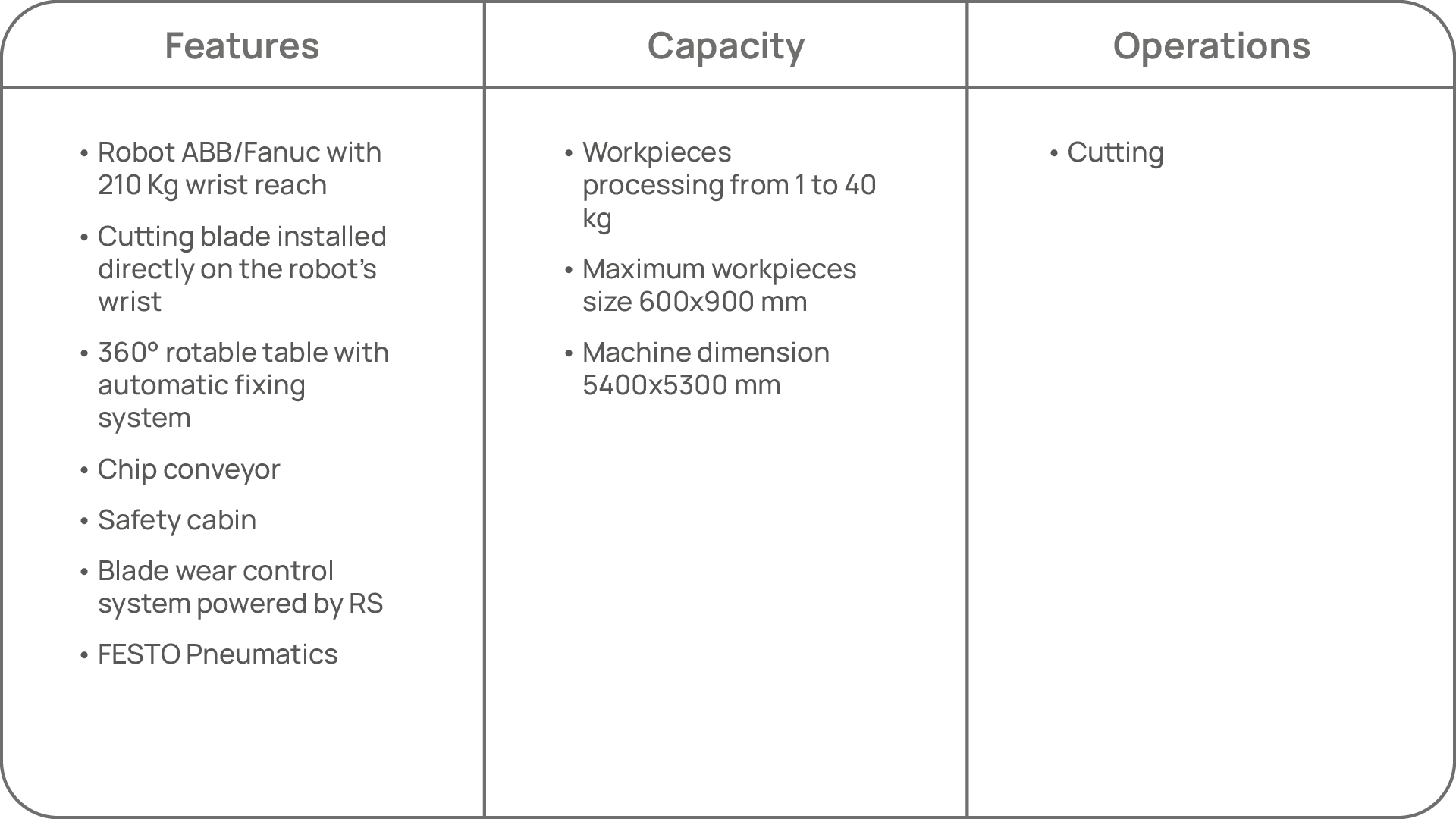

RS130 is engineered for automated cutting processes ensuring safety, precision, and efficiency.

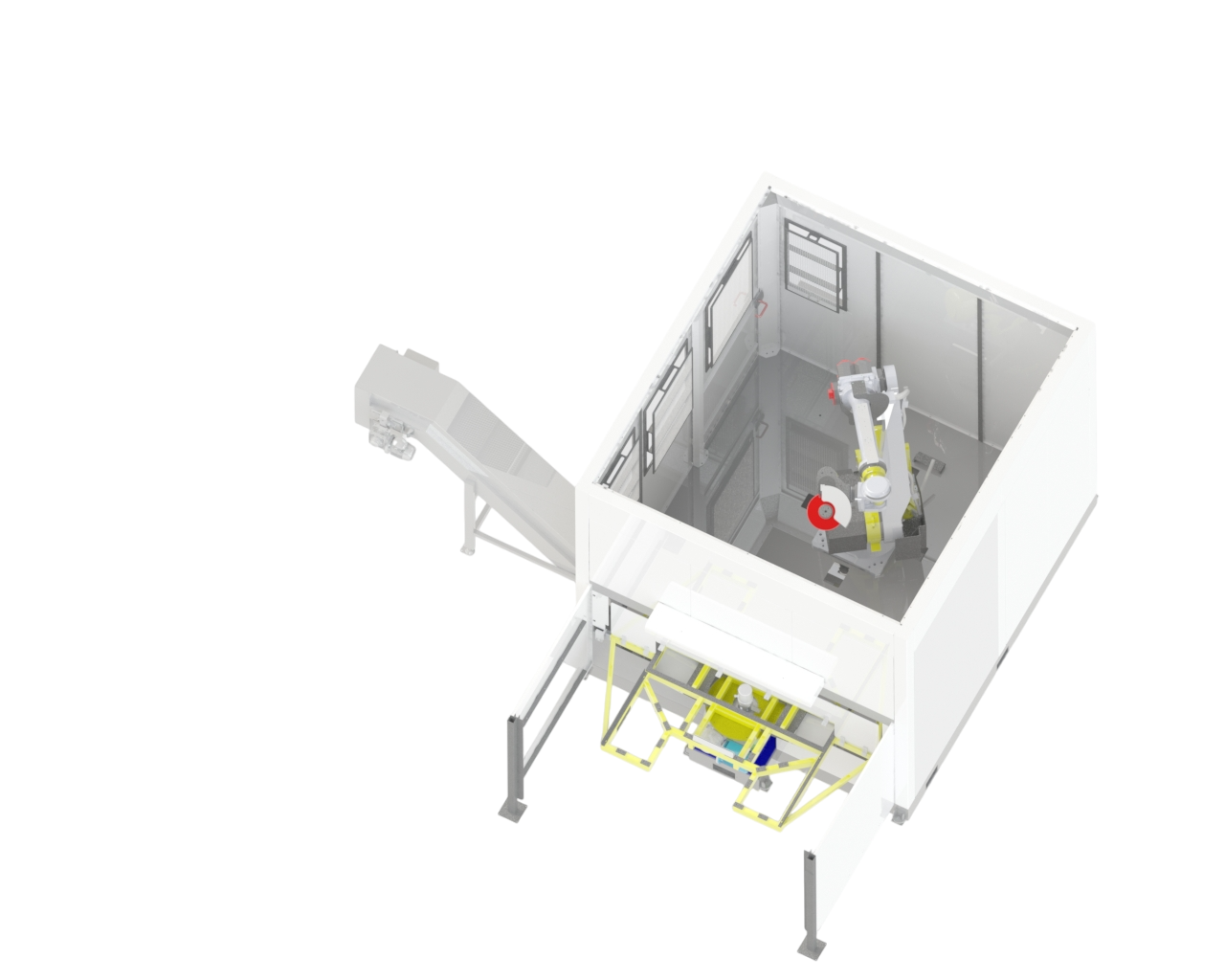

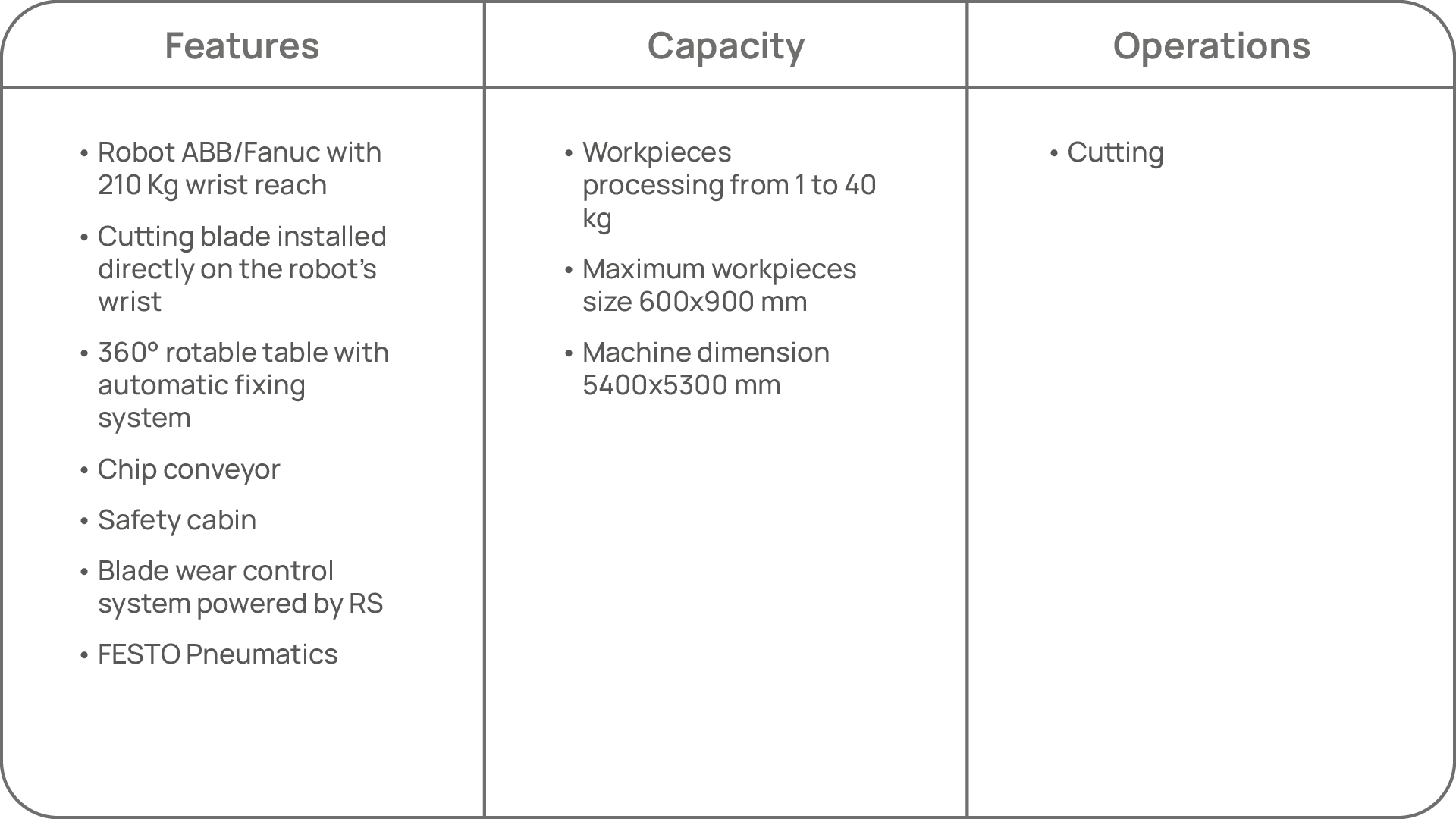

The definitive solution for cutting large castings, in complete safety! RS300 it’s created with the aim of satisfying the needs of those who need to cut large castings, automating the process.

RS300 It boasts a completely independent system, the piece is placed and clamped automatically in a 0-360° position with two stations, the robot, 6 axes with an important load-bearing structure, carries out the cutting operations with the tool itself applied on board the robot.

Cutting automation is managed by RS software that allows you to manage cutting speed and feed during processing..

Our robotic systems are designed to deliver excellent and reliable performance.